In an era where customization is at the forefront of consumer demand, various methods allow garments and fabrics to shine with unique designs. Traditional techniques such as screen printing have paved the way for innovative digital methods, each contributing its distinct advantages to the world of fashion. Among them, dtg printing has risen to prominence, offering high-quality, bespoke apparel creations.

The Science Behind the Technique

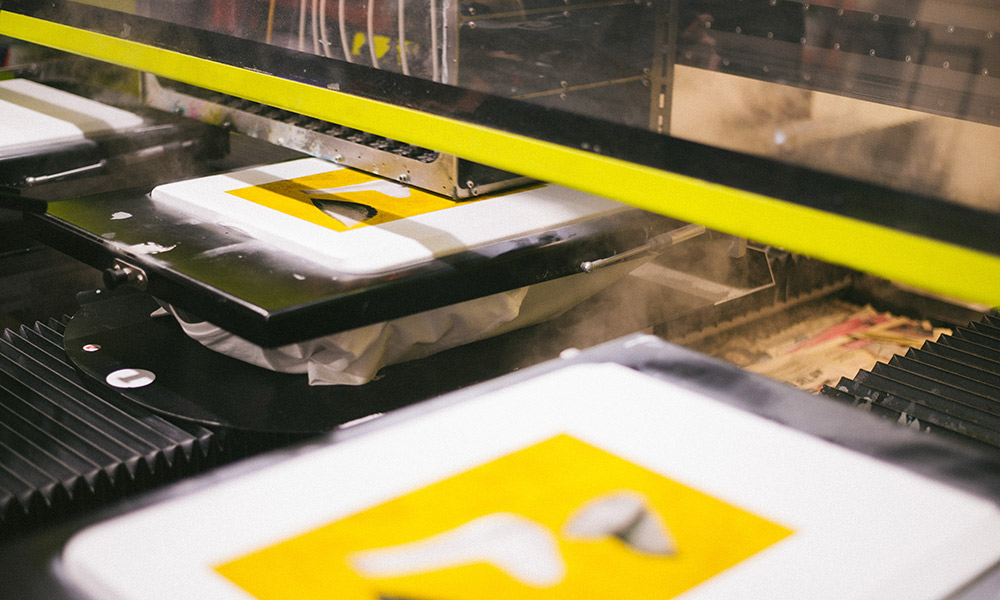

DTG, which stands for Direct-to-Garment, is not just a trend but a revolutionary printing method. Instead of transferring ink through screens or stamps, a DTG printer directly applies ink onto the fabric, much like a typical desktop printer does with paper. The method employs specialized inks that are readily absorbed by the fibers of the clothing material, ensuring a smooth and seamless finish. Given its digital nature, this type of printing captures intricate details flawlessly, reflecting true-to-design patterns. It’s this precision and adaptability that make it a favored choice for both designers and businesses alike. For those who value precision and vibrant color reproduction, DTG stands out as a superior choice.

Key Advantages Over Traditional Methods

The evolution of printing on fabric has been marked by various techniques, each with its merits. However, the DTG method brings a slew of advantages that are hard to ignore. Its foremost benefit is the unparalleled precision it offers, allowing designs to be replicated without smudges or inconsistencies. Unlike other methods, DTG doesn’t necessitate any setup costs, making it a financially wise option for smaller batches or unique items. With a quick turnaround time, clients can receive their orders promptly, offering a competitive edge in the fast-paced fashion market. The flexibility and speed of this method make it especially suited for businesses that prioritize efficiency and quality in tandem.

The Range of Materials it Supports

The versatility of DTG doesn’t end with its printing capabilities; it extends to the variety of fabrics it can cater to. Originally, cotton was the primary fabric for achieving optimal results with DTG. Yet, with continuous advancements in technology and innovative ink formulations, the method now accommodates a broader range of materials, from polyester blends to even some luxurious fabrics. However, as with any method, there are always considerations. It’s crucial to ensure fabric compatibility before embarking on large-scale projects. By doing so, businesses can guarantee the final product meets the desired standards.

Caring for DTG Printed Garments

Maintaining the pristine quality of any garment extends its life, and this holds for DTG printed apparel too. While these prints boast of durability and resistance against daily wear, certain care measures can amplify their longevity. It’s advisable to wash such garments inside out using cold water, as this preserves the design’s vibrancy. Steering clear of bleach and harsh detergents can further prevent the print from fading prematurely. Moreover, letting the garment air dry, rather than subjecting it to the intense heat of a tumble dryer, ensures the print remains intact and vibrant for years to come.

Environmental Footprint: A Greener Choice

Sustainability and environmental consciousness have become central themes in today’s production processes. DTG printing, understanding the zeitgeist, has incorporated green practices to align with these values. The inks utilized in this method are primarily water-based, eliminating the need for harmful solvents that can be detrimental to the environment. Also, the process itself is water-efficient, using significantly less water than some age-old methods. The minimal waste produced during the process further underscores its commitment to eco-friendliness, making it an attractive choice for brands that prioritize environmental responsibility.

Conclusion:

In wrapping up, the digital age has ushered in a plethora of innovations, with dtg printing firmly establishing its position at the helm. Whether it’s a budding designer eyeing to make a mark or an established brand aiming for expansion, understanding the intricacies of this method could be the key to charting new horizons in the realm of apparel design.