In the realm of heavy-duty applications, from industrial machinery to massive gates and doors, durability and reliability are paramount. A seemingly small component, like a hinge, can make a significant difference in the overall performance and longevity of such structures. One hinge type that has emerged as a true champion in heavy-duty applications is the weld-on bullet hinge. In this article, we will explore the crucial role of weld-on bullet hinges and how they contribute to the stability and efficiency of heavy-duty equipment and structures.

The Basics Of Weld-On Bullet Hinges

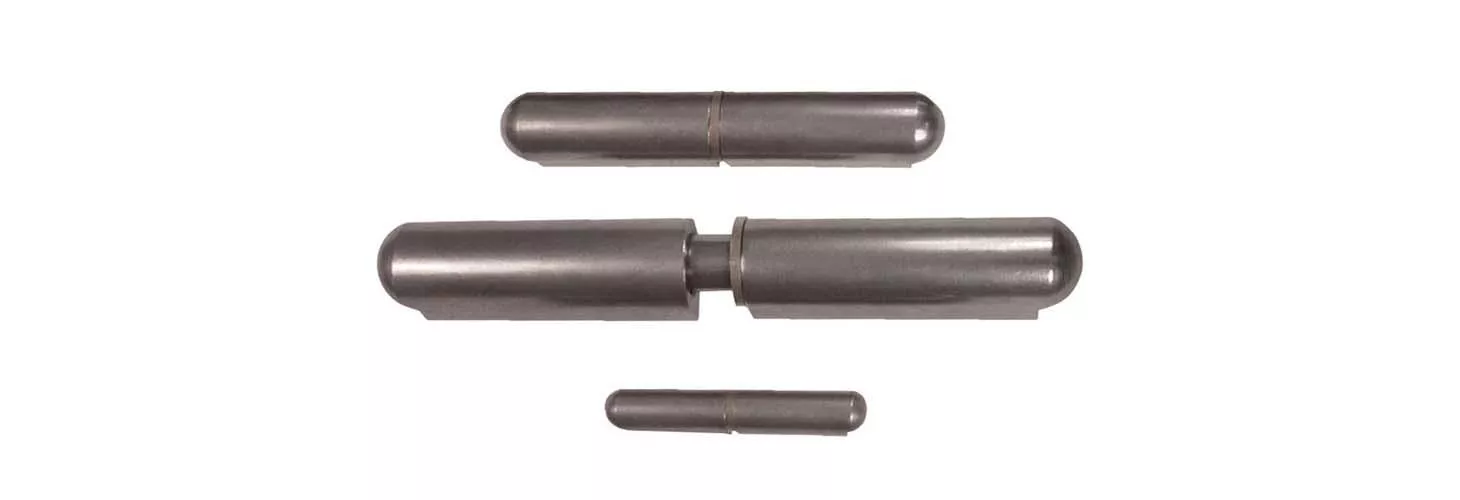

Before delving into their role in heavy-duty applications, let’s start with the basics of weld-on bullet hinges. These hinges are aptly named due to their cylindrical, bullet-shaped pin design. They are typically made of robust materials like steel or stainless steel, which are known for their strength and corrosion resistance. Weld on bullet hinges are specially designed to be welded directly onto the mounting surface, making them a permanent fixture.

Now, let’s explore why weld-on bullet hinges are so crucial in heavy-duty scenarios:

Unparalleled Strength And Durability

Heavy-duty applications demand components that can withstand immense pressure and continuous use. Weld-on bullet hinges excel in this regard. Their construction and materials provide exceptional strength and durability, ensuring that they can handle the weight and stress imposed on them.

Whether it’s a large gate on an industrial property, a heavy door in a manufacturing facility, or a piece of heavy machinery on a construction site, weld-on bullet hinges are up to the task. They are designed to endure the harshest conditions and the toughest loads, ensuring reliable performance over an extended period.

Stability And Smooth Operation

Heavy-duty equipment and structures often require a smooth and stable operation, especially in industrial settings where efficiency and safety are paramount. Weld-on bullet hinges offer a smooth pivot point, allowing for easy and controlled movement. Their design minimises friction and wear, ensuring that heavy doors and gates can be opened and closed effortlessly.

Furthermore, the stability provided by weld-on bullet hinges helps prevent sagging or misalignment over time. This stability is crucial in maintaining the integrity of heavy structures, reducing the need for costly repairs and replacements.

Resistance To Environmental Factors

In heavy-duty applications, equipment and structures are exposed to various environmental factors, including extreme temperatures, moisture, and corrosive substances. Weld-on bullet hinges, typically made of steel or stainless steel, are highly resistant to corrosion and rust.

This resistance ensures that the hinges remain in top condition even when subjected to harsh weather conditions or corrosive industrial environments. As a result, they continue to function reliably, reducing maintenance costs and downtime.

Customisation Options

Weld-on bullet hinges come in various sizes and configurations, allowing for customisation to suit the specific needs of heavy-duty applications. Whether you need a larger hinge for a massive gate or a smaller one for a heavy-duty cabinet door, there are weld-on bullet hinge options available to meet your requirements.

The ability to tailor the hinge’s size and design to the application enhances its versatility and ensures a perfect fit, contributing to the overall efficiency and functionality of heavy-duty equipment and structures.

Longevity And Cost-Effectiveness

One of the most significant advantages of using weld-on bullet hinges in heavy-duty applications is their longevity. These hinges are built to last, reducing the frequency of replacements and maintenance. While the initial investment may be slightly higher than that of traditional hinges, the long-term cost-effectiveness makes them a wise choice for heavy-duty applications.